Technical Manual

For

ITRT-ZJZ-F Series Resistor Panel For Neutral

Grounding Of Generator

For

ITRT-ZJZ-F Series Resistor Panel For Neutral

Grounding Of Generator

Ⅰ. Overview

Neutral grounding via resistance can effectively limit the intermittent arc grounding overvoltage, reduce system operation overvoltage, eliminate the system resonance overvoltage, and facilitate the single-phase grounding fault protection. It can efficiently cut off the faulty circuit in a short time and make system operate more safely and reliably.

This product series are suitable for AC power grid Generator neutral points, and can achieve power grid neutral grounding mode via grounding resistance. They are featured with high accuracy, good linearity, reliable operation, easy installation and good appearance, etc.

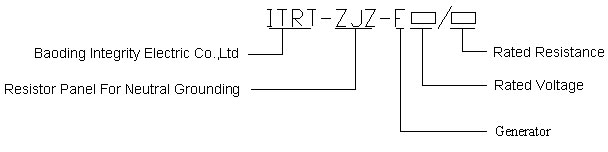

Ⅱ. Model Description

Ⅲ. Service Conditions :

1.Altitude: not more than 4000m;

2.Ambient temperature: -40oC ~ + 65oC;

3.Relative humidity: not more than 95% (25 oC) ;

4.Place of Installation: free of chemical corrosive gas and vapor or explosive dust in the air;

5.Grid frequency: 48 ~ 52Hz (50 Hz system), 58 ~ 62 Hz (60 Hz system);

6.Applicable to indoor;

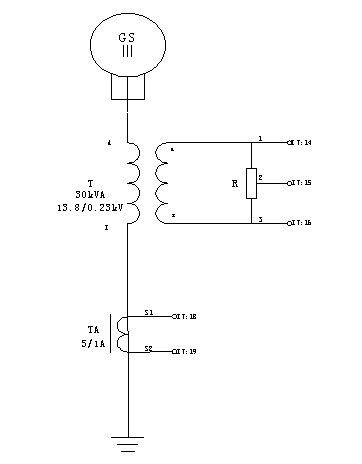

IV. Working Diagram

V. Packaging & Transportation

When the product is packed, it should be placed on the base of the packing box and secured with bolts; the cabinet body should be covered with plastic film to prevent the dust or water vapor during transportation or storage; place of delivery, equipment name and shipping weight as well as other information should be clearly marked on the resistance cabinet packing box; upon arrival, the goods should be unloaded with a forklift or crane; prior to unloading, the goods should be checked to confirm the goods is safe and free of damages or losses during transportation; it is recommended to transport the equipment to the installation site by means of the original package so as to prevent possible damage during transportation.

VI. Inspection & Acceptance

1.Upon receipt of the equipment, the user shall check it immediately.

2.Check each item given in the packing list for compliance with actual articles in respect of quantity.

3.Check the product nameplate data for consistence with the order contract.

4.Check the factory documents for completeness.

5.Check the appearance of the product for bump or deformation and the interior electrical components and connections for any damage, loss and looseness.

6.The product should be safekept or repacked properly if it is not to be put into service immediately after unpacking inspection is completed.

VII. Equipment Installation and Testing

1.Equipment Installation

The foundation, grounding system and cable duct should be prepared and incoming cables and outgoing cables and their protective pipes should be embedded before product installation. The product should be installed in accordance with relevant standards and specifications as well as the requirements of the equipment ventilation, cooling, installation and maintenance.

Transport the equipment to the installation site with a forklift, remove the bolts for securing the base, take the equipment out of the box and remove the package so as to prevent damages to the shell; the forklift should be aligned with the angle at the bottom shell so as to avoid damages to the equipment bottom plate when operating the forklift.

This product can be installed in a dedicated foundation or concrete bench and should be placed horizontally. The product is secured onto the foundation with anchor bolts by passing through the bolt holes at the cabinet bottom. If the product is installed on the concrete foundation, it is recommended to adopt expansion bolts.

Check and tighten all fixing and connecting bolts in the cabinet to ensure a firm fastness and reliable connection. The shell should be grounded reliably via the grounding bolt.

2.Inspection and Test before Putting into Operation

After the equipment is seated properly, open the front door of the cabinet, check the equipment and wiring in the cabinet, and note that all packaging materials must be removed from the box before power connection so as to avoid fire accident; check the insulators carefully for any damages, and contact the supplier immediately in case of damaged parts; check all electrical connection to confirm connection is secure and reliable; check whether all fixing bolts are tightened firmly.

Test before putting into operation: Measure the resistance value of resistance element; measure insulation resistance; carry out power frequency voltage withstand test with the voltage not more than 85% of delivery test voltage in accordance with specified standards; be ready for putting the equipment into service.

VIII. Product Maintenance

This grounding resistance cabinet has high reliability and generally can be maintained without power cutoff. It is recommended to carry out inspection and maintenance strictly according to the safe operation procedure while the main transformer or bus in the substation is being inspected and maintained with power cutoff.

Disconnect the resistance cabinet from the system;

Open the cabinet door and directly check the box inside for any abnormality;

Perform cleaning;

Check insulators for any damages and confirm the insulation performance with a megger;

Check the resistance element for integrity and measure the resistance value which shall be within 10% error;

Check internal connection for reliability;

Check the bolts for tightness.

Baoding Integrity Electric Co., Ltd

Address: Building 3, University Technology Park, No. 5699, North 2nd Ring, Baoding, Hebei Province.

Tel: 0312-3917283

Fax: 0312-3917281

Email: itrtdq@163.com